Laser metal cutting has been applied to create precise, fast and aesthetically pleasing cuts. That brings a new step forward in the metalworking industry. Most laser cutting machines on the market today use CO2 lasers or Nd:YAG lasers with exactly the same principle.

Specifically, the principle of laser metal cutting

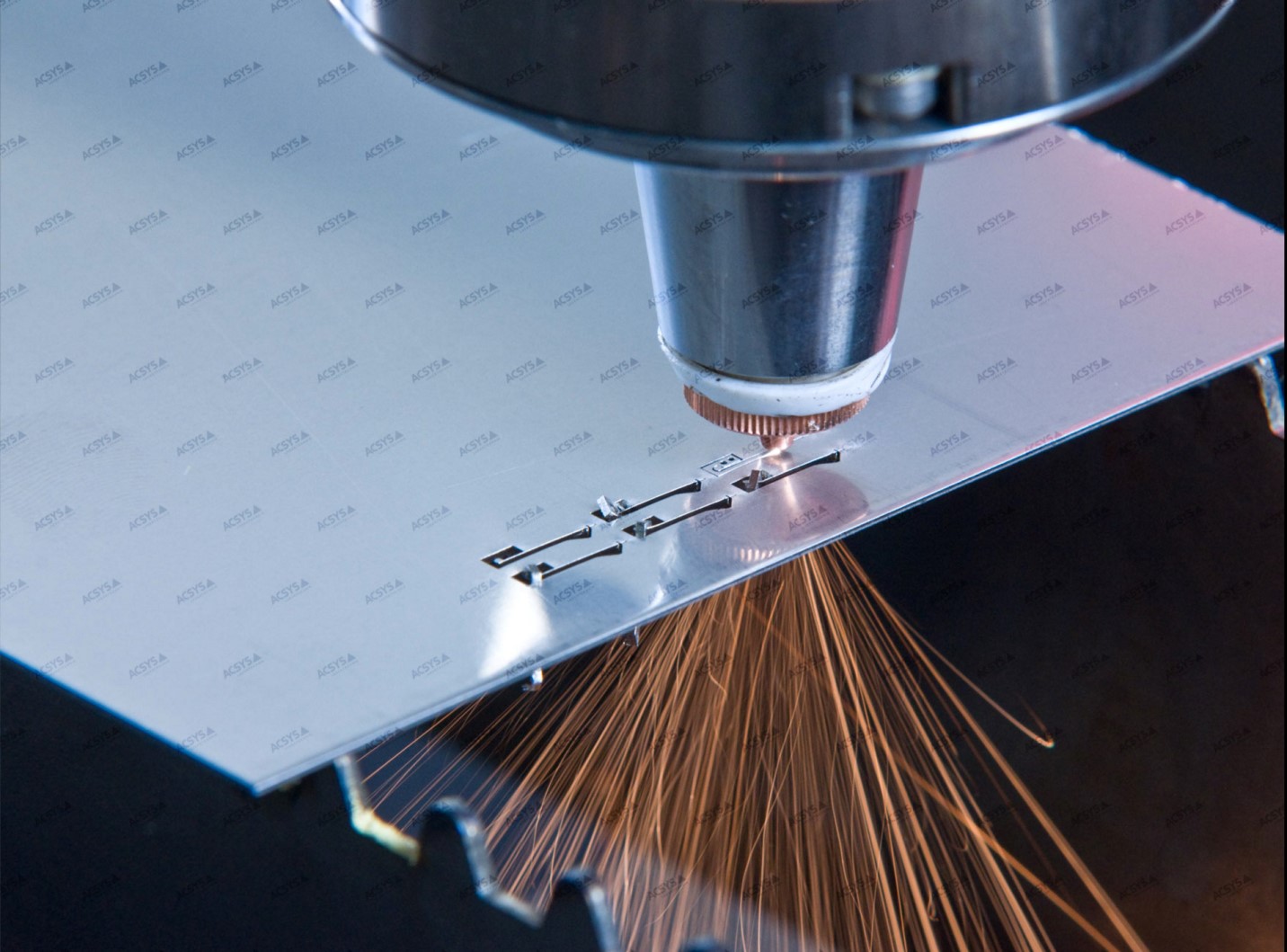

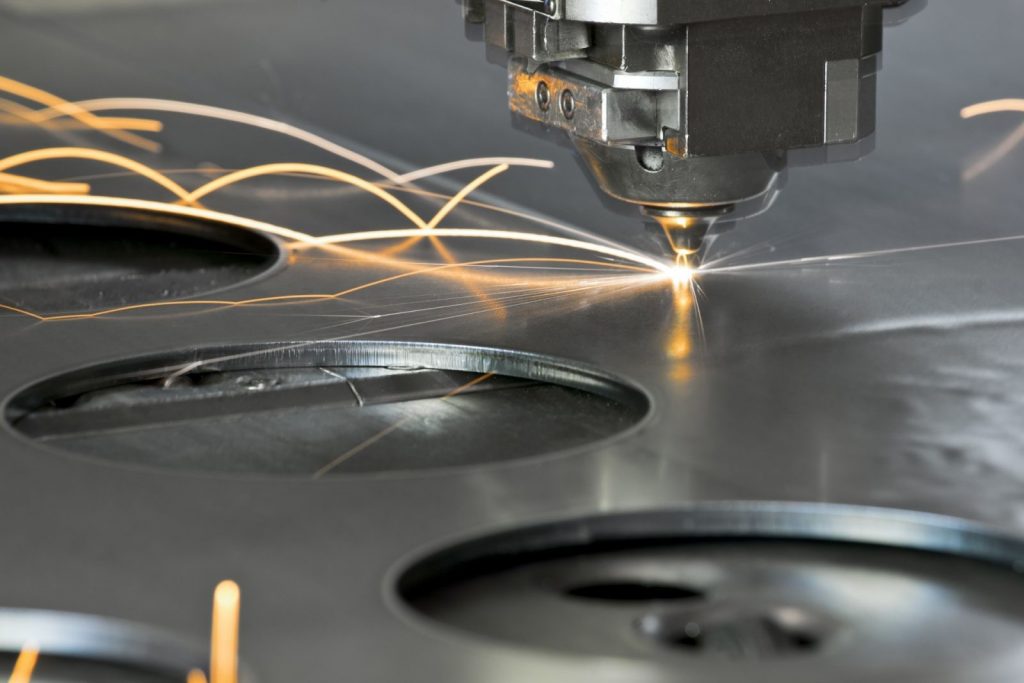

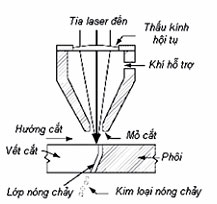

First, a high-energy beam generated by the laser generator is focused on the workpiece surface by means of a lens system. This beam then heats the material and creates a localized region of molten material, usually less than 0.5mm in diameter.

At this point, the molten material is pushed out of the machining area by a high-pressure gas stream, coaxial with the laser beam. For some materials, this flow of gas accelerates the cutting process by the chemical and physical action of the laser beam.

The locally melted material area is moved along the part surface in a trajectory and generates a cut, which can be fully automated allowing 3D shapes to be cut depending on the purpose and needs of the user. consumers.

Some common metals are laser cut

Steel: Carbon steels are easy to cut with a laser. As the alloy content in steel increases, the cutting process becomes more difficult. Particularly for tool steels with high tungsten content, the cutting speed is very slow and there is slag if not processed meticulously.

Aluminum: Compared to steel, aluminum is much more difficult to cut because they reflect a large amount of laser light and the amount of heat transferred to the part is large and fast. If the laser focus is not adjusted correctly, the beam may be reflected back to the injection system, causing damage to the optical components as well as making it more difficult to machine after the cutting process has ended.

Titanium and its alloys: due to the reaction with oxygen and nitrogen, they become brittle and break easily, so cutting these metals by laser seems very impossible, especially for details in aviation. and medicine made of titanium. If necessary, inert gases such as argon can be used to obtain better quality cuts without causing them to become denatured.