The development of laser fiber technology

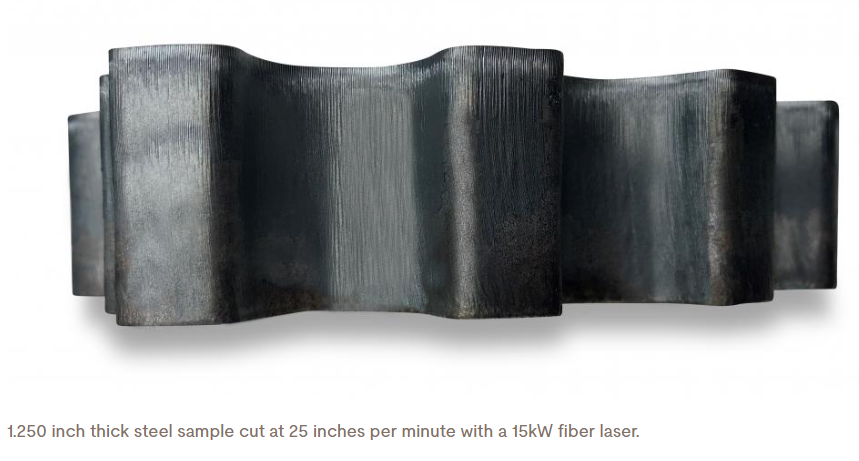

- Fiber laser cutting is one of the “breakthrough” technologies introduced into the metalworking market since the CO2 laser was first introduced in the 1980s. Fiber laser technology is considered a breakthrough and revolutionary because it affects the processing of steel plate. And opportunities are easy to spot. Moreover, in a short period of time, we have realized the advantages of fiber lasers used to process steel plates. In just five years, fiber lasers have reached the 4kW threshold that CO2 lasers take almost four times as long to reach. After ten years fiber lasers have reached 15kW for cutting. To be fair, Fiber Lasers – some exceed 20kW – have been used by other industries for years in applications other than sheet metal cutting.

Advantages of Fiber Laser technology

- The main advantages of flat sheet metal cutting with Fiber laser technology stem from the compact, Fiber-to-Fiber, monolithic, solid-state design configuration that requires no maintenance and offers lower operating costs. than can be achieved with comparable CO2 lasers. The fiber laser beam characteristics also result in much faster cutting speeds than CO2 as we will explore below.

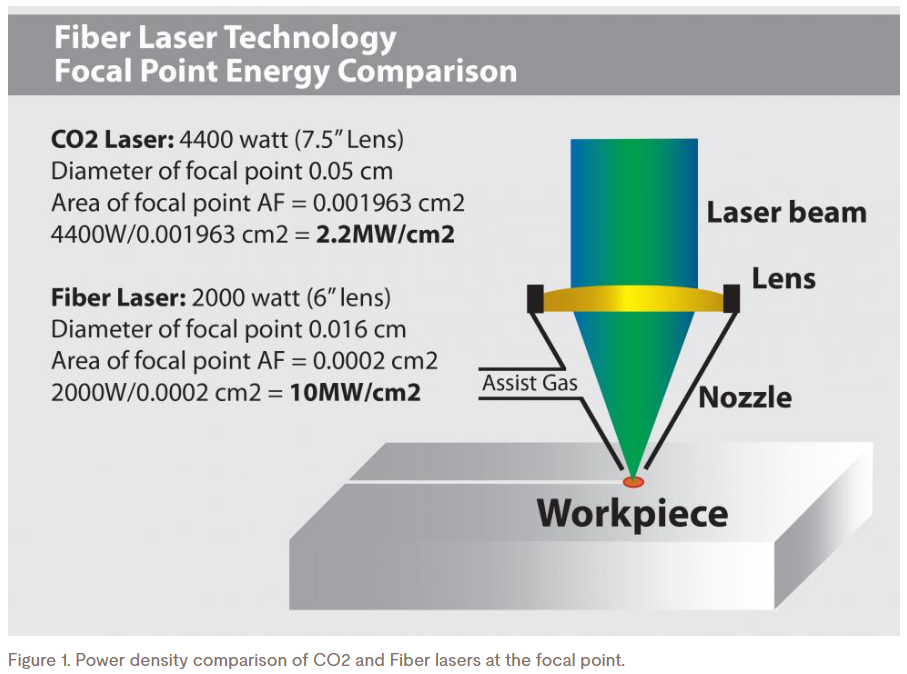

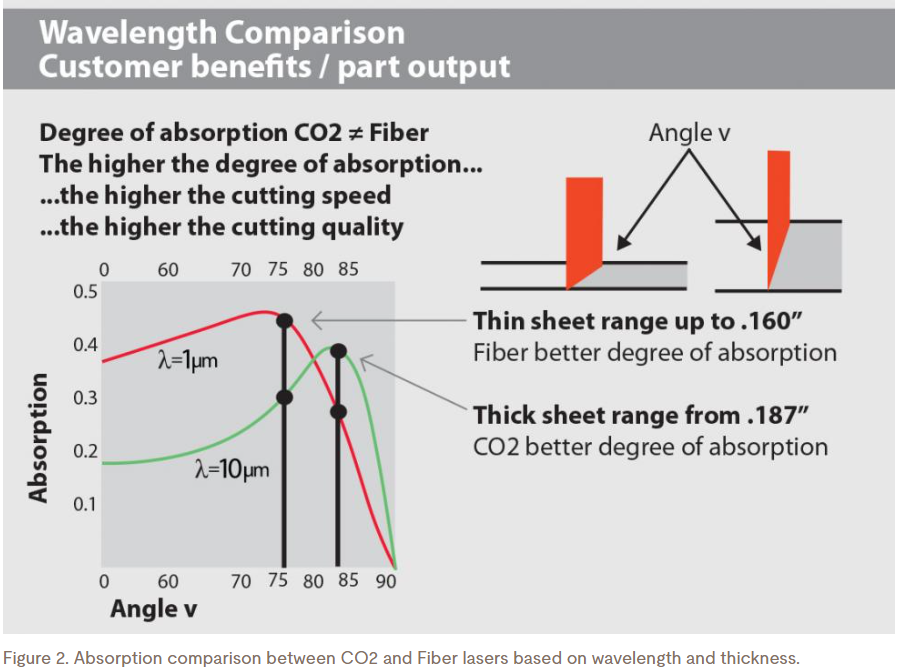

- The focused beam of even a 2kW Fiber laser exhibits 5 times greater power density at the focal point when compared to a 4kW CO2 laser. It also possesses 2.5 times greater absorption characteristics due to the shorter wavelength of fiber lasers. (see Figure 1 and Figure 2).

- The higher absorption of the optical fiber wavelength and the higher energy density produced by the focused beam combine to achieve a fivefold increase in cutting speed in materials less than 1/2 inch thick.

- Fiber laser cutting systems can certainly cut over 1 inch thick with higher fiber laser power and even faster cutting using nitrogen as the assist gas, but the “optimal point” is where the benefits are realized. Most significantly at 1/2 inch and below range for steel when compared to CO2 systems. Certainly, if you are machining stainless, aluminum, brass or copper materials, fiber laser technology is the fastest and most economical regardless of thickness.

Figure 1: energy density between CO2 and Fiber laser technologies

Figure 2: absorption comparison between CO2 and Fiber lasers based on wavelength and material thickness

- The speed benefit is most profound when nitrogen is used as the backing gas because the molten material is pushed out of the cut by the nitrogen as quickly as it melts. The higher the laser beam energy density, the faster the material is brought to the molten state, the faster the feed rate.

Sheet metal parts are 1/8 inch thick and rarely cut with a Fiber Laser machine.

- Effective use of the speed benefits from high power Fiber lasers requires careful planning and management of all processes. With three to four times the power and half the operating costs of a CO2 laser, the financial benefits can be a game changer. The result is a lower cost per part, a higher potential profit margin, and a shorter payback period. Don't forget the added benefit of increased machine capacity now that you're processing normal part volumes much faster, giving you the opportunity to take on extra work to further increase your sales and profits.

- Fiber lasers can cut copper, brass and aluminum much better and safer than CO2 because the beam is absorbed more easily and is not reflected. Fiber laser operating costs are typically half what a CO2 system can provide due to the lower power consumption and high electrical efficiency of fiber lasers.

- One of the latest advancements in Fiber laser cutting is the addition of 'Beam Shaping' technology which changes the beam profile to cut thick sheets with Oxygen. Because the fiber laser is transmitted through an optical fiber, the beam profile is inherently small and creates a narrow channel as it focuses through the material. Although this is beneficial for power density when cutting with nitrogen gas as the support gas, this is not the case for oxygen-assisted cutting. When cutting with oxygen, a wider beam profile with lower power density is preferred as it creates a wider channel in the material to push the molten steel out. Wider beam profile results in faster cutting speeds and improved blade quality on thicker steels. 'Beam Shaper' technology achieves the wider beam profile needed to achieve this increased performance.

There are many aspects to operating a CO2 laser cutter that do not exist when operating a Fiber laser cutting machine:

- High power Fiber laser cutting machine can cut 5 times faster than conventional CO2 laser machine and save half the operating cost.

- Fiber laser cutting machines need no warm-up time – usually about 10 minutes per start up for CO2 lasers.

- Fiber laser cutters require no beam path maintenance such as mirror or lens cleaning, bellows inspection and beam alignment. This can cost an additional 4 or 5 hours per week for the CO2 laser.

- The fiber laser has a fully encapsulated fiber optic beam path from the power source and the fiber path to the cutting head. The beam is not contaminated with the beam path as is the case with the CO2 laser.

- The fiber optic beam path maintains a uniform cutting head beam centering.

Since the integrity of the fiber beam is uniformly constant, so are the cutting parameters, requiring much less adjustment than a CO2 laser.

Sheets of metal larger than 1/4 inch thick are cut with a Fiber laser cutter.

- What happens to all this time saved? Higher productivity and greater machine capacity! With Fiber lasers that cut five times faster, produce three to four times more parts per unit time, and coupled with 50% lower operating costs than CO2, this presents an opportunity. large based on generating more machine capacity.

Conclude

The question of which technology is right for you really depends on your operations. How well does the system fit your particular application? How much faster and more cost-effective will your parts be produced? With this in mind, careful analysis of pertinent data is required, including scope of application, operating costs, throughput, cost of ownership, and of course investment costs.

(Source: Bystronic https://www.bystronic.com/usa/en-us/news/130204-co2-vs-fiber-laser)