Laser Technology

Concept

There are many applications for metalworking, including laser technology, which provides exceptional cutting quality and enhanced performance for a wide variety of metals. In which there are two types of lasers: CO2 and Fiber. CO2 Laser initial investment cost is low but maintenance cost is high.

Lasers can cut with different material thicknesses, before deciding which type to invest in, there are a few factors to pay attention to:

- Material Type

- Material Thickness

- Requirements for cutting quality

- Basic structure of the laser system

- Resonance power supply

- Ray guide unit

- Cutting head

- Laser classification

- CO2

- Fiber

- Diode

- YAG (yttrium-aluminum-garnet)

- Fiber laser application

Based on laser quality, then Fiber laser will be the first choice for precision machining applications or anywhere you need small offset or machining quality. Types of metal that can be machined by Fiber laser

- Ordinary steel

- stainless steel

- Aluminum

- Brass

- Copper

- Titan

The principle of creating a laser

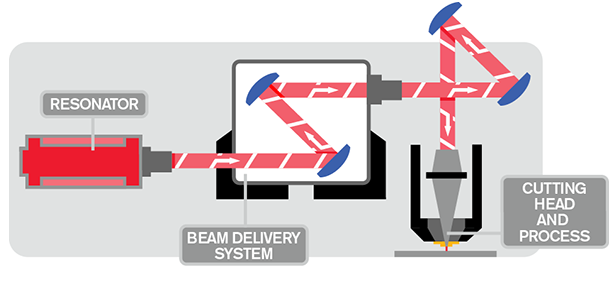

CO2

CO2 laser, high voltage is applied to the CO . mixer2, female2 and He in the resonator to generate the laser. The laser beam is then reflected and formed by a chain of reflectors that will deliver the laser to the cutting head.

Principle of creating laser by CO2 . technology

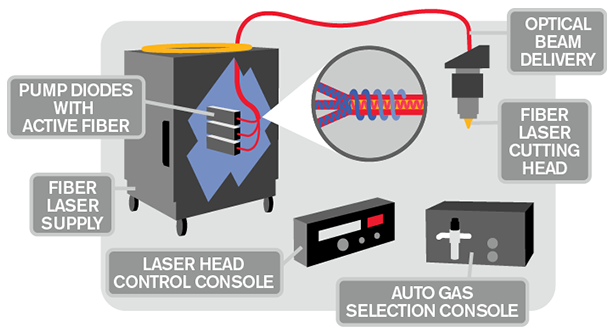

Fiber laser, the solid-state laser source is generated a laser which is routed through the fiber-optic cable to the cutting head. Fiberglass transfers the beam with the right beam quality to the cutting material.

The principle of creating lasers with Fiber technology